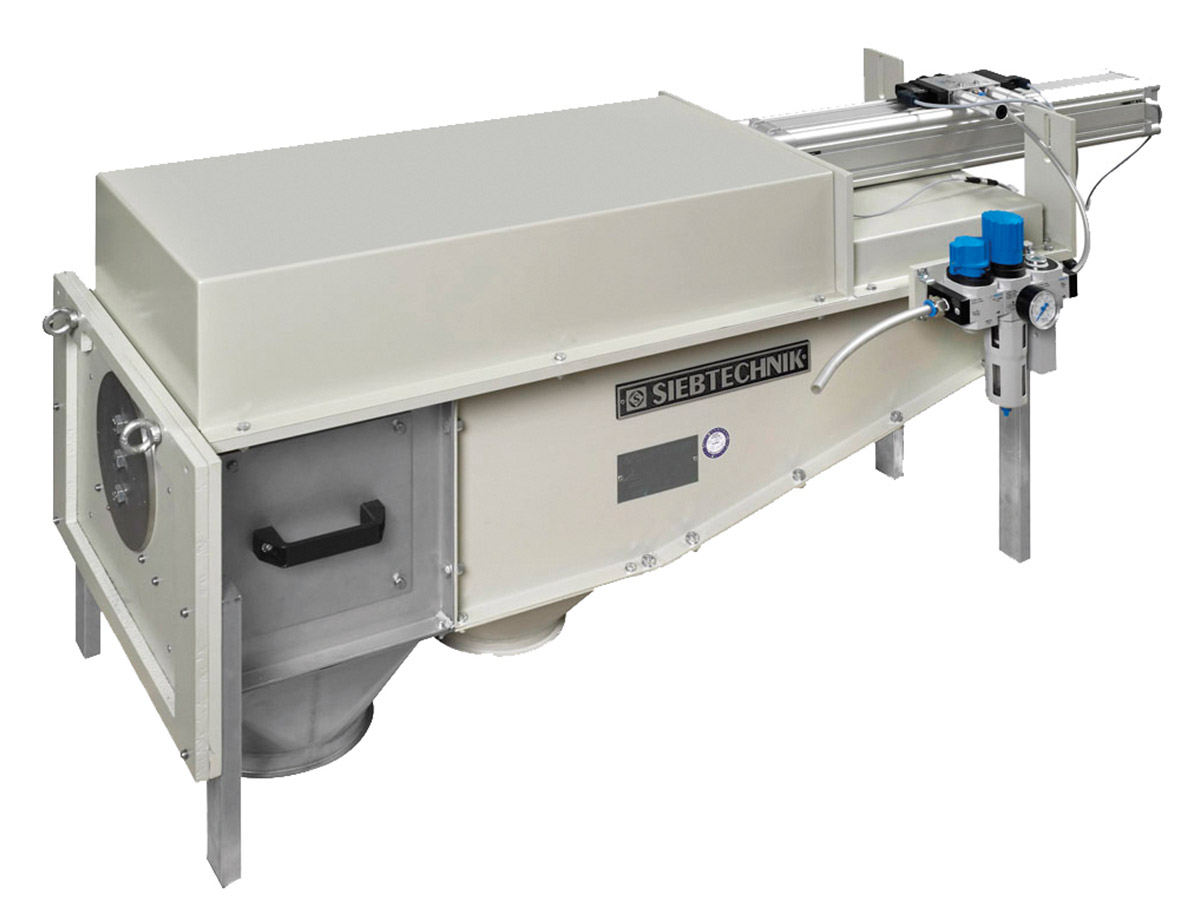

Клинкерный пробоотборник тип KPN

Operating Behavior & Mechanical Characteristics

Together with the piston sampler, the clinker sampler ranks amongst those samplers removing a selective sample from the material flow. For this purpose, a sampling spoon, which is filled with sample material over a defined period of time, is run into the product flow pneumatically. When the sampling spoon is drawn back, it is removed inside the sampler housing by a piston and the material sample pre-classified over a rigid sieve grid. The fine material thus obtained can be taken over for further analysis at a pipe socket. The coarse parts are taken over at a further pipe socket and fed to the principal material flow again.

Technical specification

| Clinker sampler | KPN 130x600 | |

|---|---|---|

| Diameter of the sampling spoon | mm | Ø 80 |

| Sample volume approx. | dm³ | 3 |

| Weight | kg | 280 |

Accessory Sampling

A wide range of accessories is available for all SIEBTECHNIK TEMA sampling equipment. Based on long years of experience SIEBTECHNIK TEMA ensures optimum results for your tasks.

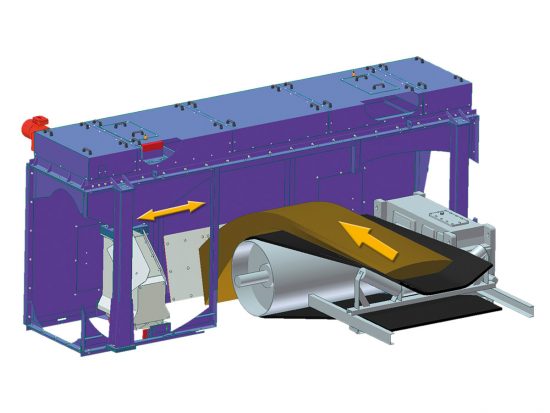

Apart from sampling equipment made up of downpipes and air slide conveyor systems, you can also obtain from us samplers for representative sampling of moved bulk materials, e.g. obtained from conveyor belts. We likewise offer you complete sample preparation plants with dividing equipment, crushers, sampling equipment, …

Should you want to combine several sampling units by means of a pneumatic post system, we are also able to offer you here a solution customised to your requirements right up to fully automatic laboratory preparation.

Advantages

- Sampling from material flow

- Low-wear and low-maintenance design+