Пульсирующие ситовые установки

Pulsator jig

Expert in density separation

The SIEBTECHNIK pulsator jig is specially designed for the separation of light material from heavy material in grain size > 1 mm. This includes the separation of harmful materials from e.g. sand and gravel, slags, building rubble and contaminated soils as well as the separation of different ores.

Density separation is an essential component in the processing of minerals and in recycling. For successful separation according to density, especially if there is only a slight difference in density, it is often not sufficient simply to whirl the material around in a counterflow. Rather It is necessary to provide a vertically pulsating flow through the material bed that allows the material to stratify.

Operational behaviour and mechanical characteristics

The excenter drive causes the top box, which is filled with water, to vibrate harmoniously.

The water pulsates in time with the vibrations and drives the strokes necessary for separation.

The feed material is moved forward towards the discharge by the tilt of the screen panel, the strokes and the flow of water.

At the same time the strokes cause the deposited material to be stratified according to density.

At the end of the screen panel the floating light material (e.g. carbonized wood, shells, waste rock, etc.) at the water surface is carried away to the side or to the front by a discharge chute positioned transversely to the direction of transport.

The heavy material (e.g. quartz, gravel, etc.) is discharged forward through the height-adjustable weir or other discharge unit.

The separated materials are dewatered on suitable equipment, for example vibrating troughs.

The main component of the SIEBTECHNIK pulsator jig is a base frame of steel on which is mounted the top box fitted with wedged-in, easily replaceable, steel-reinforced polyurethane screen panels. The top box is flexibly connected to the vibratable lower box via compensators.

The lower box is connected to the excenter drive, which is adjustable for stroke length and frequency and is fitted under it, by connecting rods.

Collecting tanks fitted under the lower box receive and carry away the fine material.

Above the top box there is a discharge chute for the light material and a height-adjustable weir for discharge of the coarse heavy material.

This passive discharge system is advantageous as regards wear and tear, as there is no need for permanent movement in the abrasive material.

The weir is controlled electrically by means of an automatic float scanning device .

Technical specification

| Pulsator jig | SK 8 | SK 16 | SK 24 | |

|---|---|---|---|---|

| width of jigging bed | mm | 800 | 1600 | 2400 |

| length of jigging bed | mm | 2500 | 2500 | 2500 |

| surface of jigging bed | m² | 2 | 4 | 6 |

| other length available on request | ||||

| capacity* (gravel) | t/h | max. 50 | max. 120 | max. 180 |

| feed grain | mm | 2 to 32, max. 60 | ||

| water needed | m³/h | to approx. 150 | to approx. 250 | to approx. 400 |

| motor power | kW | 11 | 15 | 22 |

| stroke height | mm | for all machine sizes adjustable to 120 | ||

| stroke frequency | min-1 | for all machine sizes adjustable to 100 | ||

| weight without material | kg | approx. 5000 | approx. 9000 | approx. 12000 |

| * The capacity depends on grain structure, grain size, difference in density between light material and heavy material, light material content and even spreading of the material along the whole width of the jigging bed. The use of an adjustable conveyor trough is recommended. |

||||

Accessories for pulsator jigs

A comprehensive range of accessories is available for all SIEBTECHNIK pulsator jigs. Whether it’s wear protection, screen cloths, spring suspension, drive, control equipment – with its decades of experience SIEBTECHNIK gets you the best result for your requirement.

Naturally our machines can be perfectly combined and offer the optimum solution as a package.

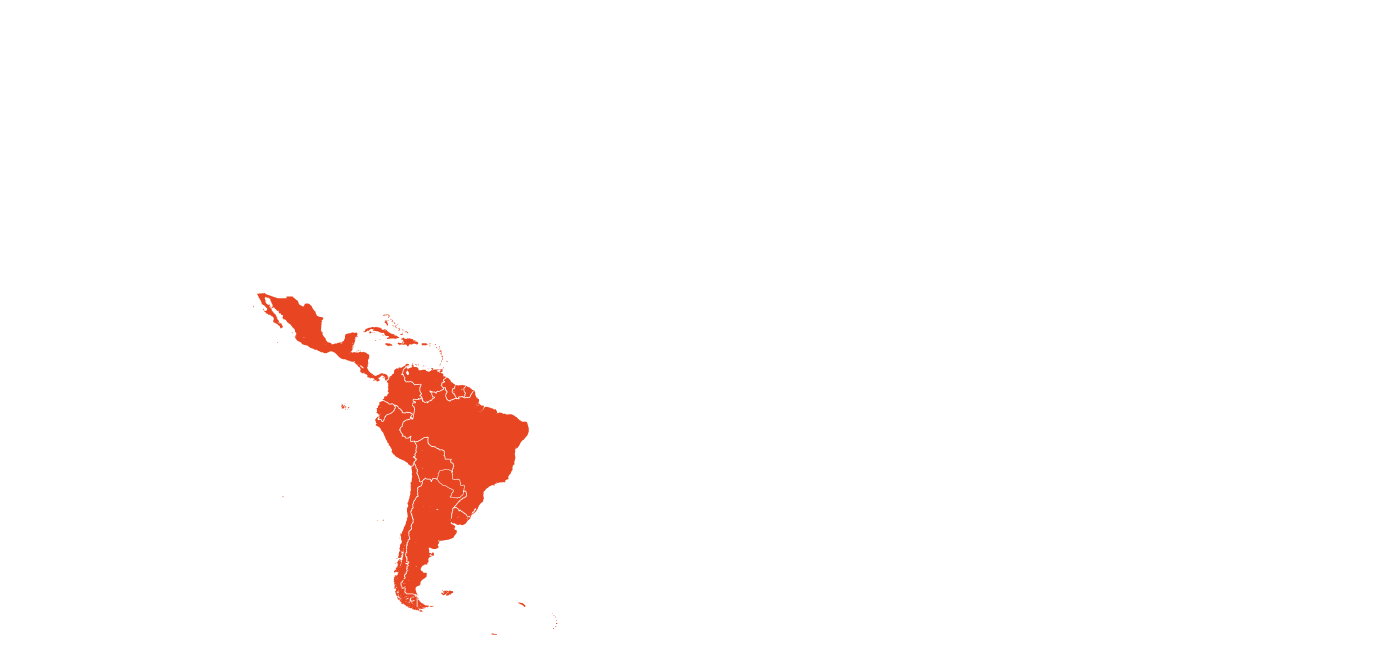

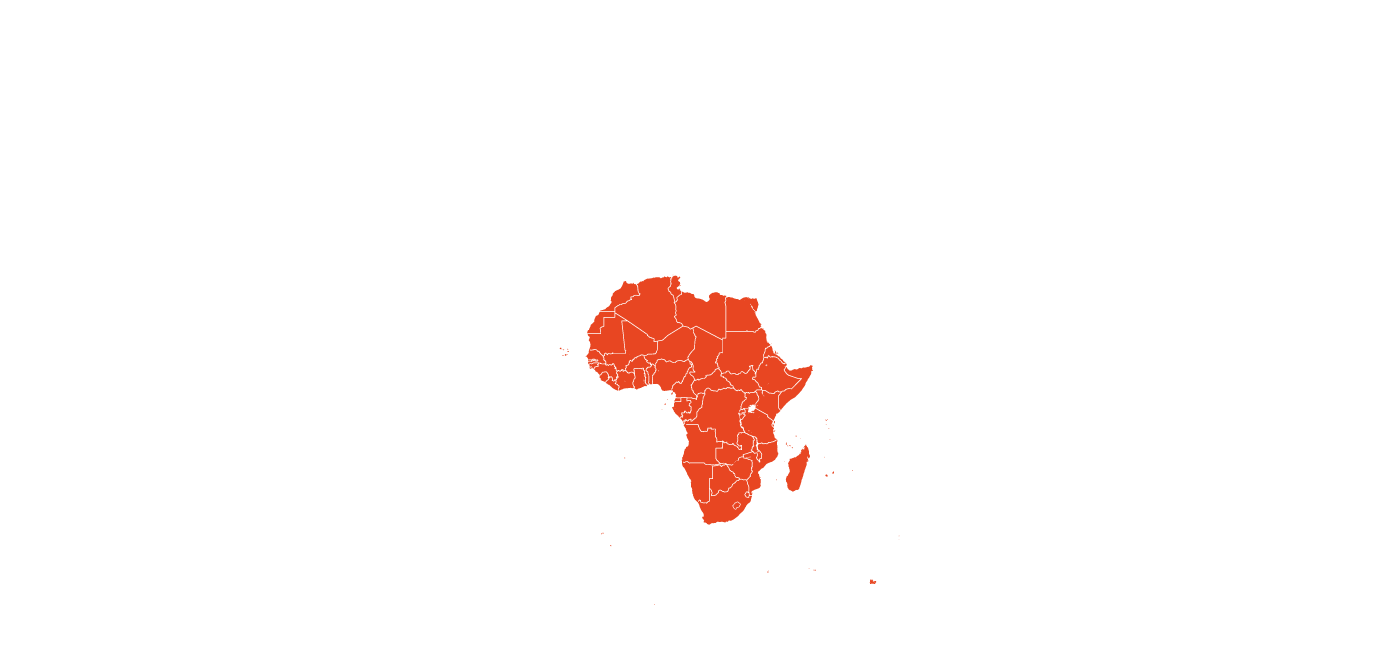

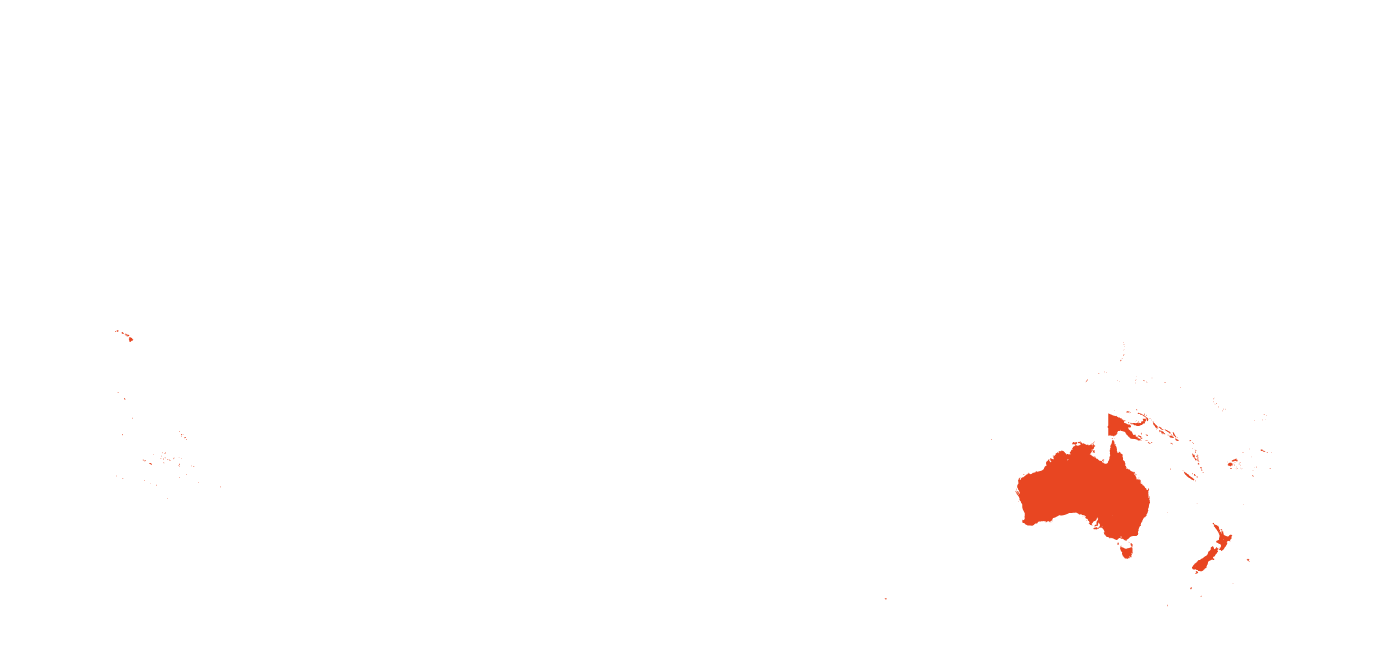

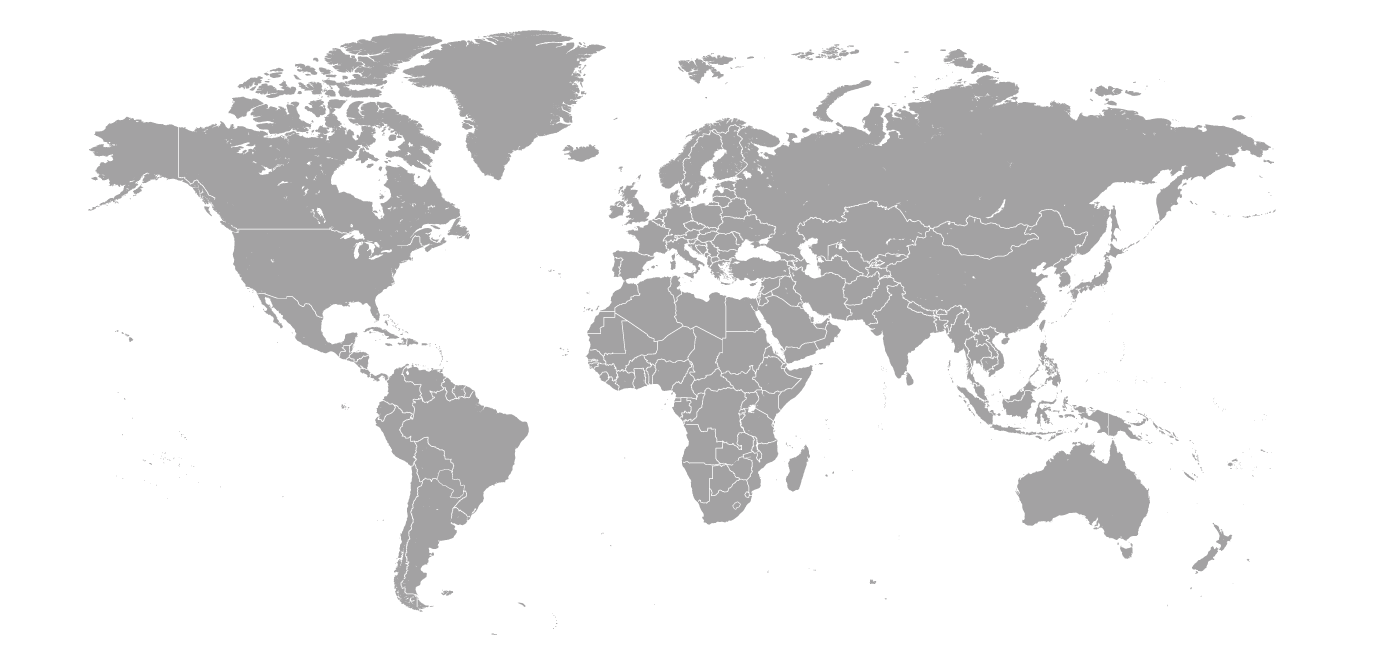

Области применения

- Базальт

- каменный уголь

- доменный шлак

- меловой песок

- Уголь

- Уголь из угольного бассейна

- угольные прутья

- Бетонный песок

- Снос отходов

- Доломит

- Мелкий уголь

- Гравий

- Граувакка

- Твердая порода — твердый камень

- Шлак сжигания

- Помет

- Минералы

- Руда

- Мелкий гравий

- Пеллеты (агломерат)

- Пеллеты (Полимер)

- Пемзовый песок

- Песок

- Песок из каналализации

- Скрап

- Ракушечный песок

- Измельченный материал

- Кварцевый песок

- Шлак

- Тантал

- Отходы

- Шлаковые отходы

- Гранит

Advantages

- high separating accuracy

- low energy consumption

- low-noise

- good vibration insulation

- robust design

- long-life time-tested components

- Optimally adapted drive concept

- Low-maintenance and repair-friendly

- Can be integrated into existing installations