Глицерин (фармацевтический)

The basics of Glycerine

Glycerine is an organic compound from the group of sugar alcohols. It is used in various industries, e.g. in the food industry, cosmetics or medicine.

Glycerine (C3H8O3) is a transparent, viscous substance. Another common name for glycerine is propane-1,2,3-triol.

In nature, glycerine is mainly found in fats and oils. It also plays an important role as an intermediate product in various metabolic processes in most living organisms.

In the past, glycerine was either obtained petrochemically from propene with the intermediates ally-chloride and epichlorohydrin, or chemically as a by-product in the saponification of natural fats and oils to produce soaps.

Due to the production of Bio-Diesel and the resulting glycerine, glycerine production has shifted.

Glycerine — Production

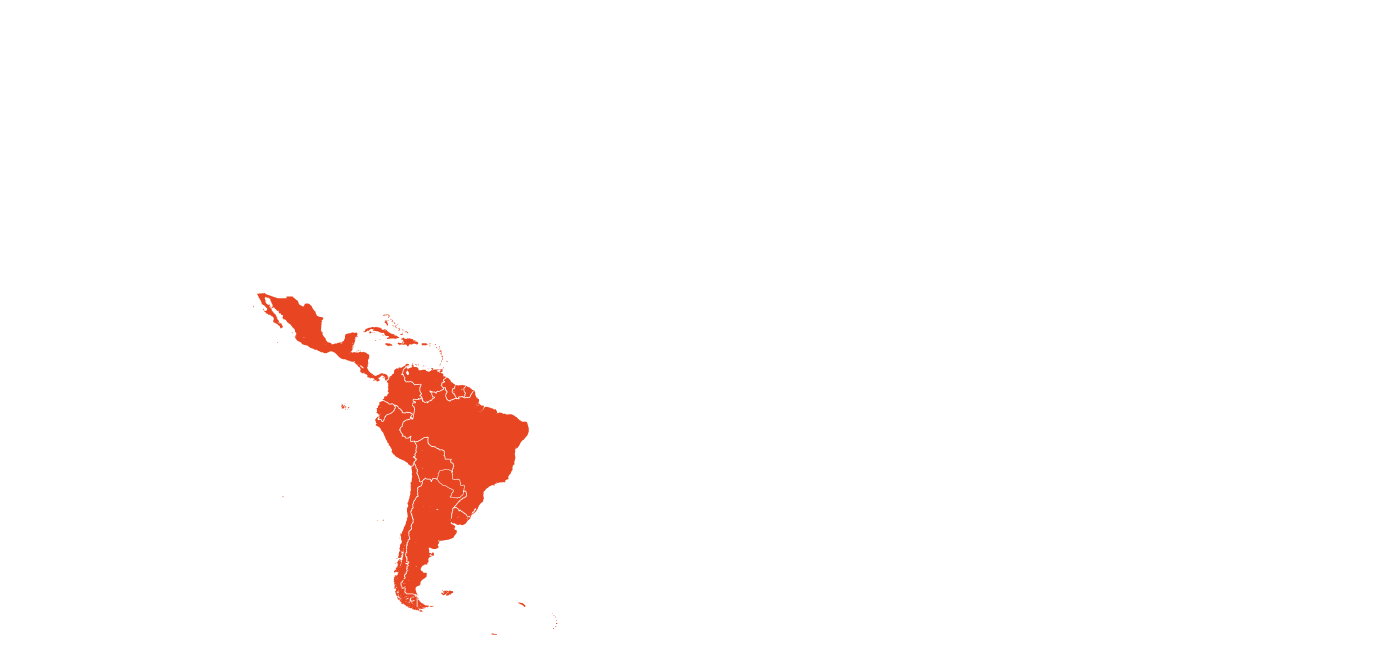

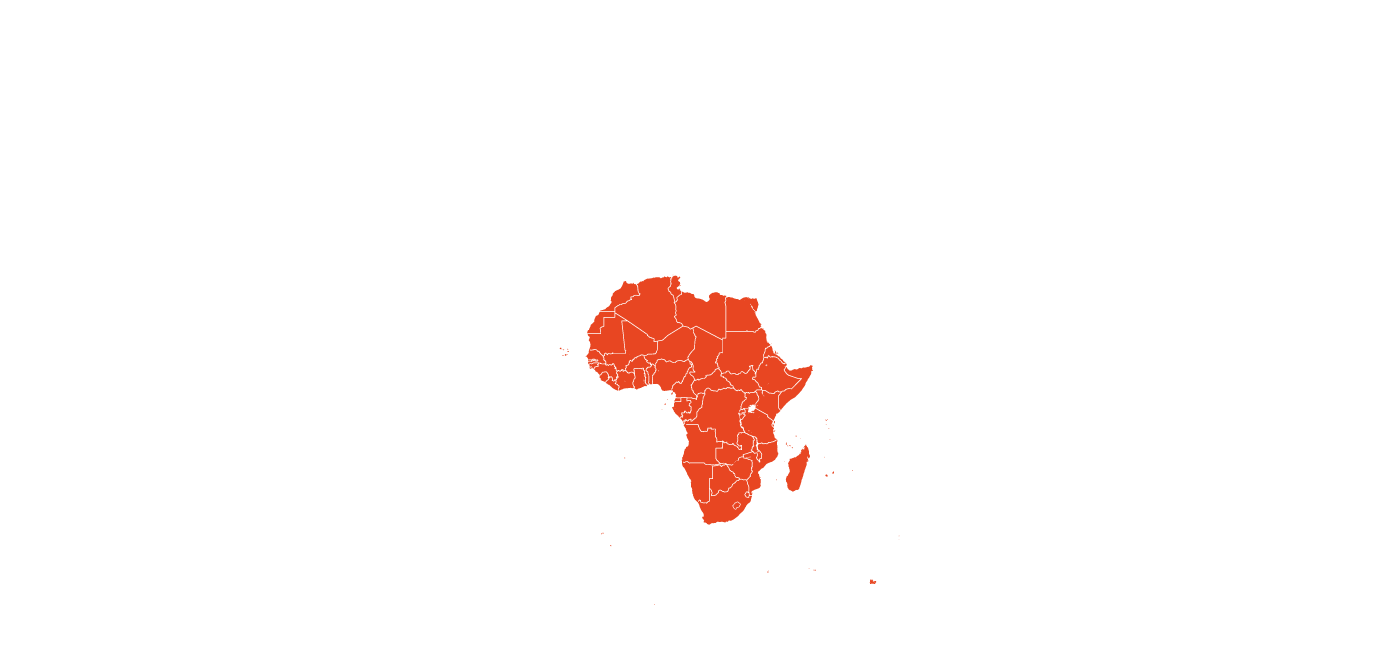

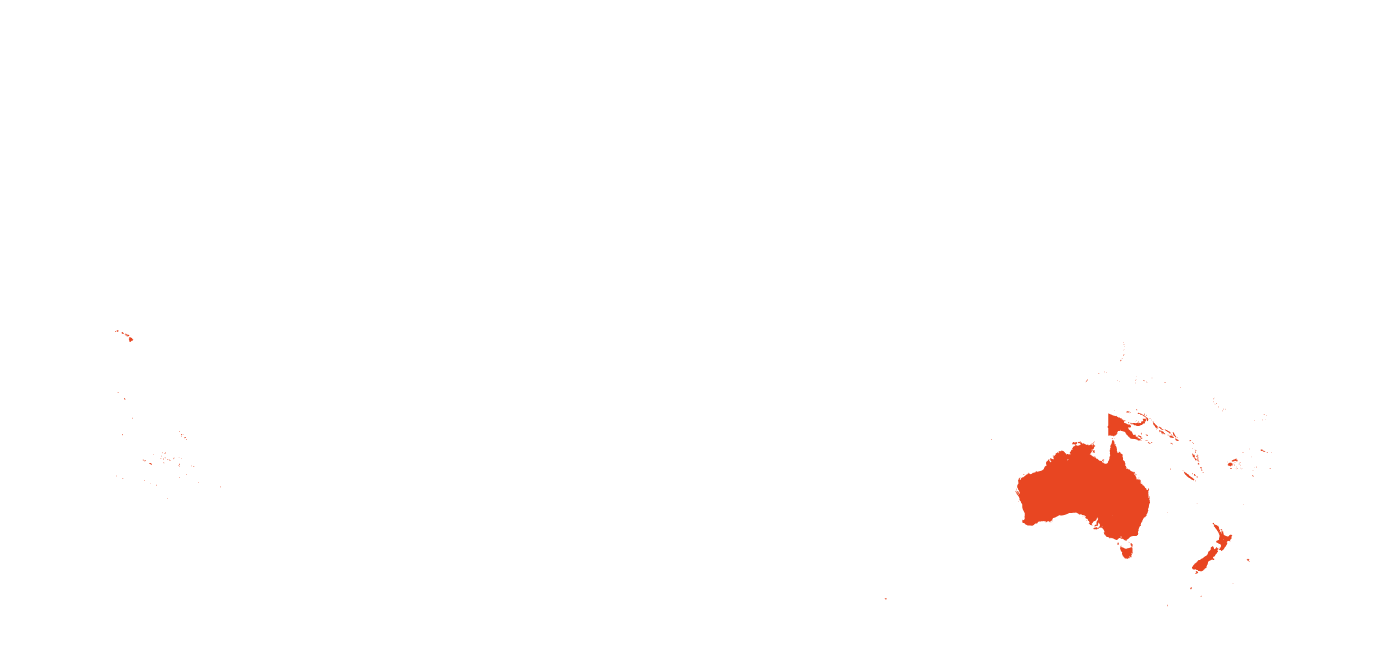

| Raw materials for Bio-Diesel production | |

|---|---|

| Rapeseed plant or rape oil | Use mainly in Europe |

| Animal fats | Use mainly in Europe/USA/Japan |

| Soybeans/Soya oil | Use mainly in USA/Asia |

| Canola rape | Use mainly in Canada |

Example with rape as raw material

Food & Dairy — As a food additive, glycerine has the designation E 422 and is used for humectant and/or sweetener purposes.

Food & Dairy — As a food additive, glycerine has the designation E 422 and is used for humectant and/or sweetener purposes.

Cosmetics — In cosmetics, glycerine is used as a moisturizer.

Cosmetics — In cosmetics, glycerine is used as a moisturizer.

Industry — Glycerine is used as an educt in many manufacturing processes. It is also used as an antifreeze, lubricant and plasticizer.

Industry — Glycerine is used as an educt in many manufacturing processes. It is also used as an antifreeze, lubricant and plasticizer.

Pharmaceuticals — In this field glycerine is used as a medicinal substance and laxative.

Pharmaceuticals — In this field glycerine is used as a medicinal substance and laxative.

Glycerine Processes

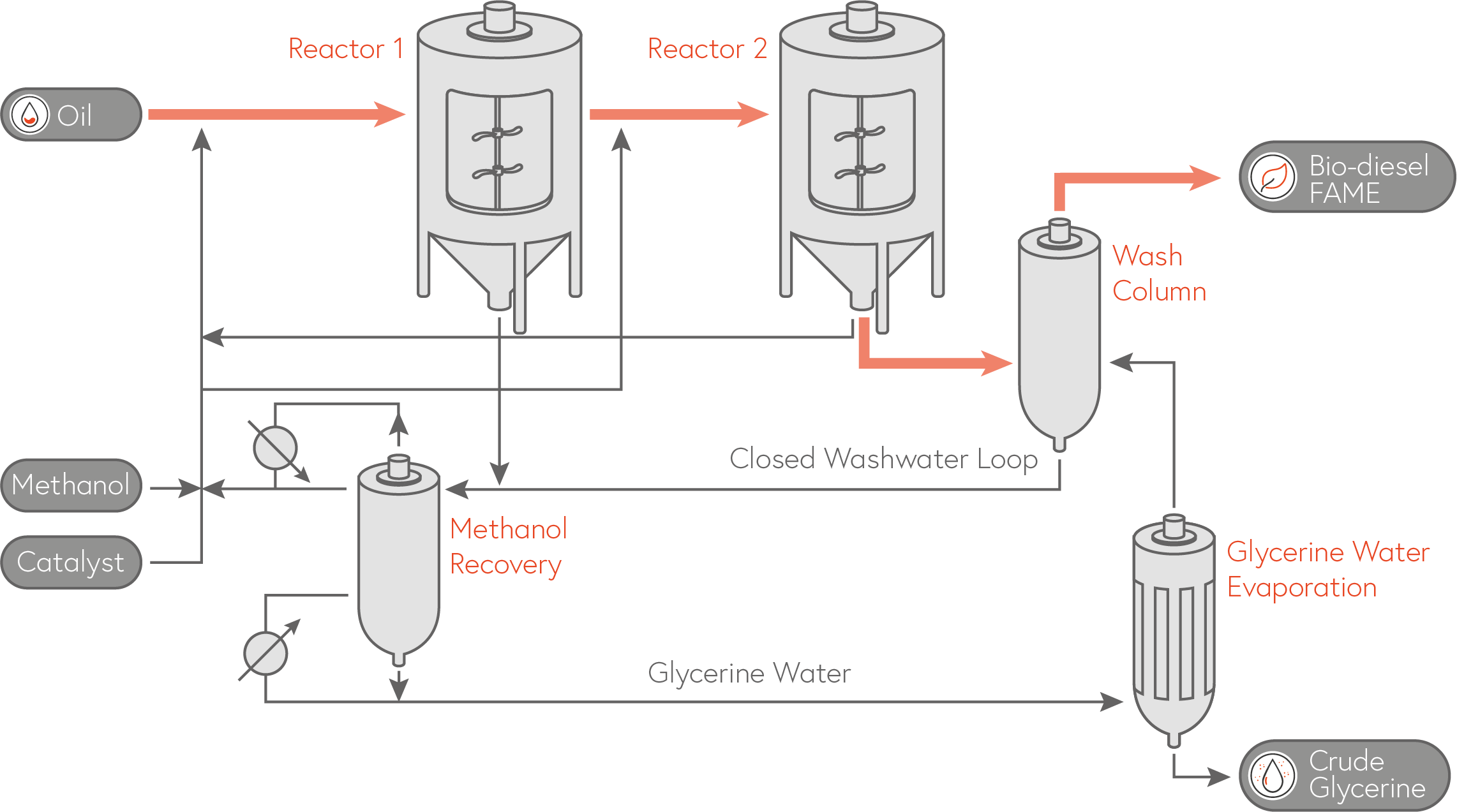

Bio-Diesel Production

Bio-Diesel Production

Bio-Diesel is produced by transesterification of fats/oils and methanol. This reaction is usually catalysed by a basic catalysis, with glycerine being a by-product.

![]()

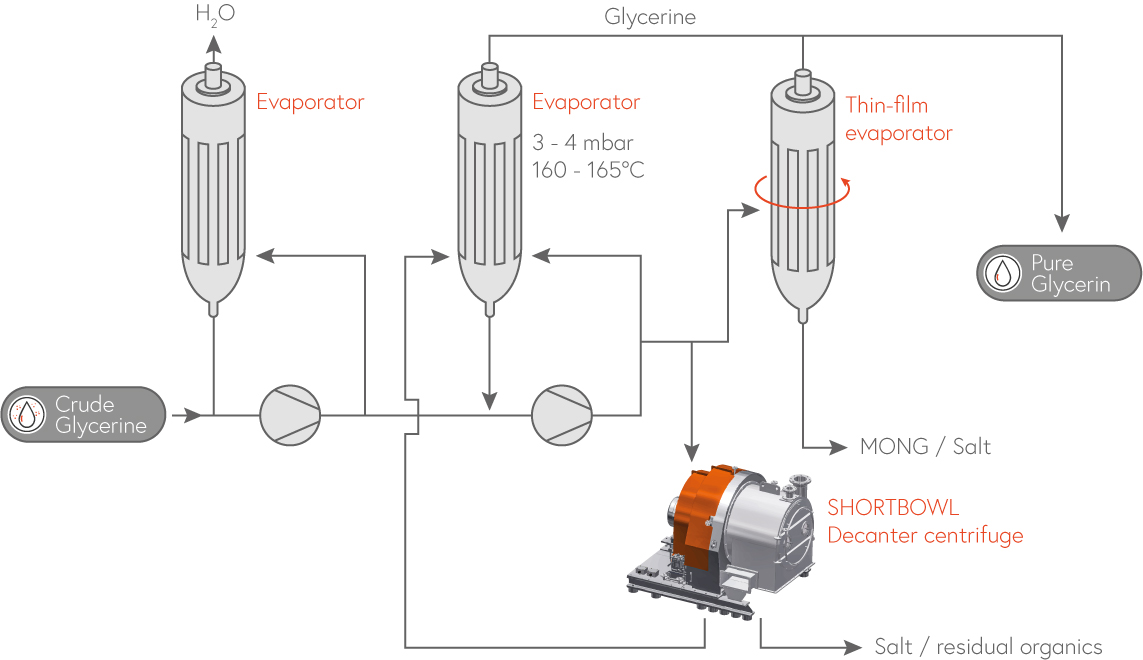

Glycerine Refinement

Glycerine Refinement

The resulting raw glycerine contains water, salts and other residues (MONG). In order to produce glycerine of pharmaceutical quality (purity 99.5 %), various purification steps are carried out. Among other things, the existing solids are separated from the glycerine.

![]()

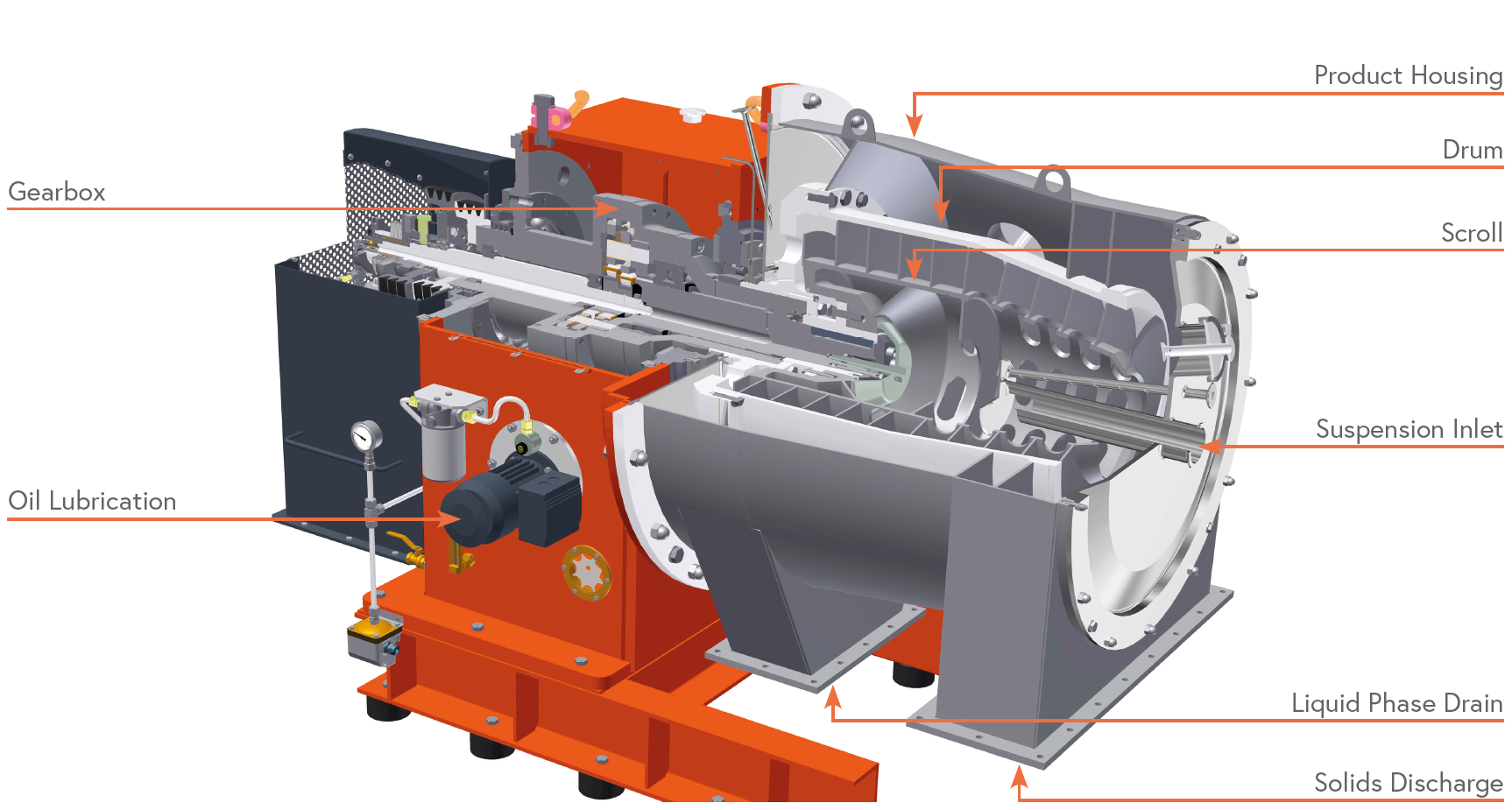

SHORTBOWL Decanter Centrifuge

Advantages in the production of pharmaceutical grade glycerine

Material: SHORTBOWL decanters are used particularly successfully for solid/liquid separation in a suspension hot stream.

Cantilever Design: No bearings or shafts in the hot product area. Product and drive area are separated from each other.

Circulating oil lubrication: The still occurring temperatures can be easily controlled by the circulating oil lubrication and an integrated oil cooler.

Average product parameters

Suspension Temperature: T = 170 – 200°C

Suspension Solid Concentration: Csolid = 10 – 30 Gew.-%

Particle Size: d50 = 80 – 300 µm

| SHORTBOWL Decanter Centrifuge | Liquid [l/h] | Solid matter [kg/h] |

|---|---|---|

| 250 | 0-1000 | 0-100 |

| 400 | 1000-3000 | 200-1000 |

| 500 | 3000-8000 | 1000-2000 |

| 600 | 8000-15000 | 2000-3000 |

| Typische Maschinengrößen Zentrifugen | ||