De-watering and drying of styrenic polymers

INEOS: De-watering and drying of styrenic polymers

Things that change the world — Polymers — INEOS Styrolution — The new ASA plant in Texas.

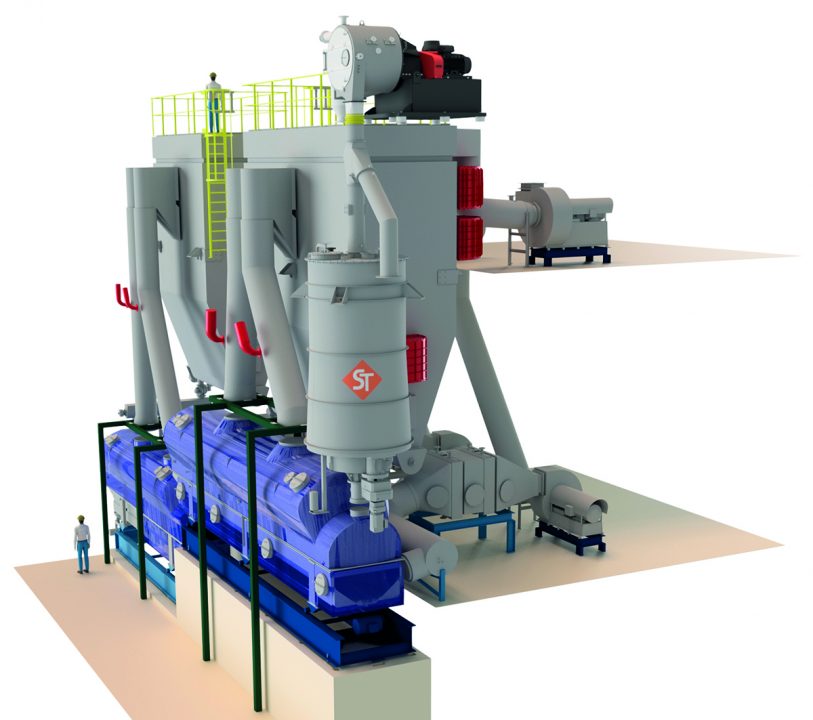

In close collaboration with its sister company TEMA PROCESS, SIEBTECHNIK TEMA supplies a highly sophisticated dewatering and drying solution for INEOS Styrolution’s new ASA plant in Bayport, Texas: Grafted rubber particles are mechanically dewatered with a pusher centrifuge and subsequently thermally dried using a two-stage continuous fluid bed dryer which is provided by TEMA PROCESS.

SIEBTECHNIK TEMA’S SOLID — LIQUID SEPARATION CENTRIFUGE SOLUTIONS FOR POLYMERS

Polymers have a broad use in everyday life. Each polymer exhibits a unique set of properties qualifying it for certain applications. These different sets of properties are accompanied by diverse solid — liquid separation challenges within the production processes. This creates a demand for highly efficient specially designed separation solutions.

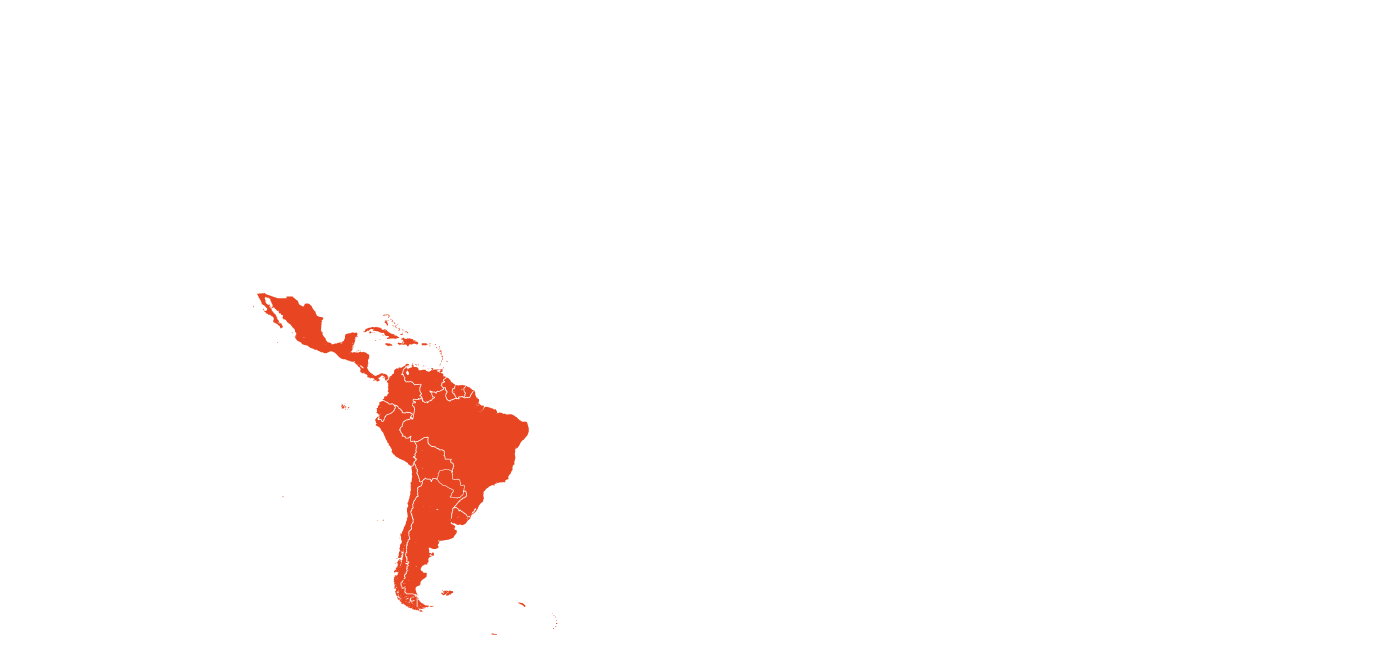

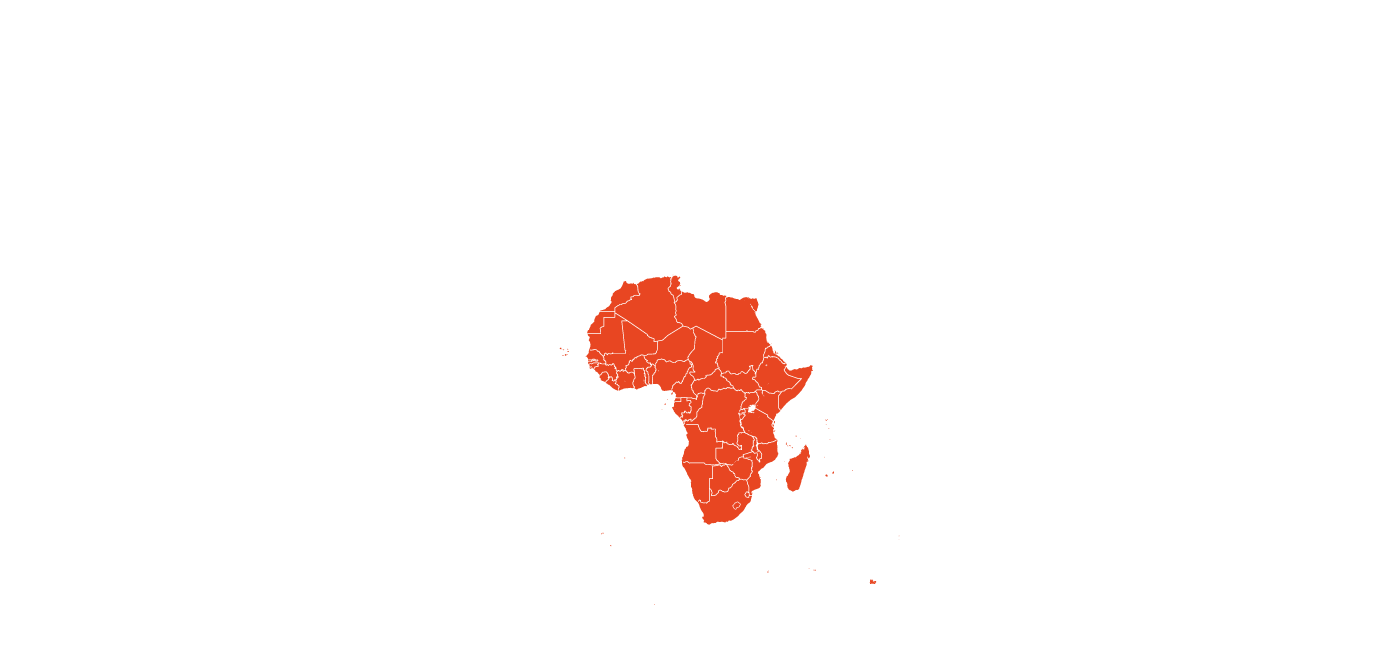

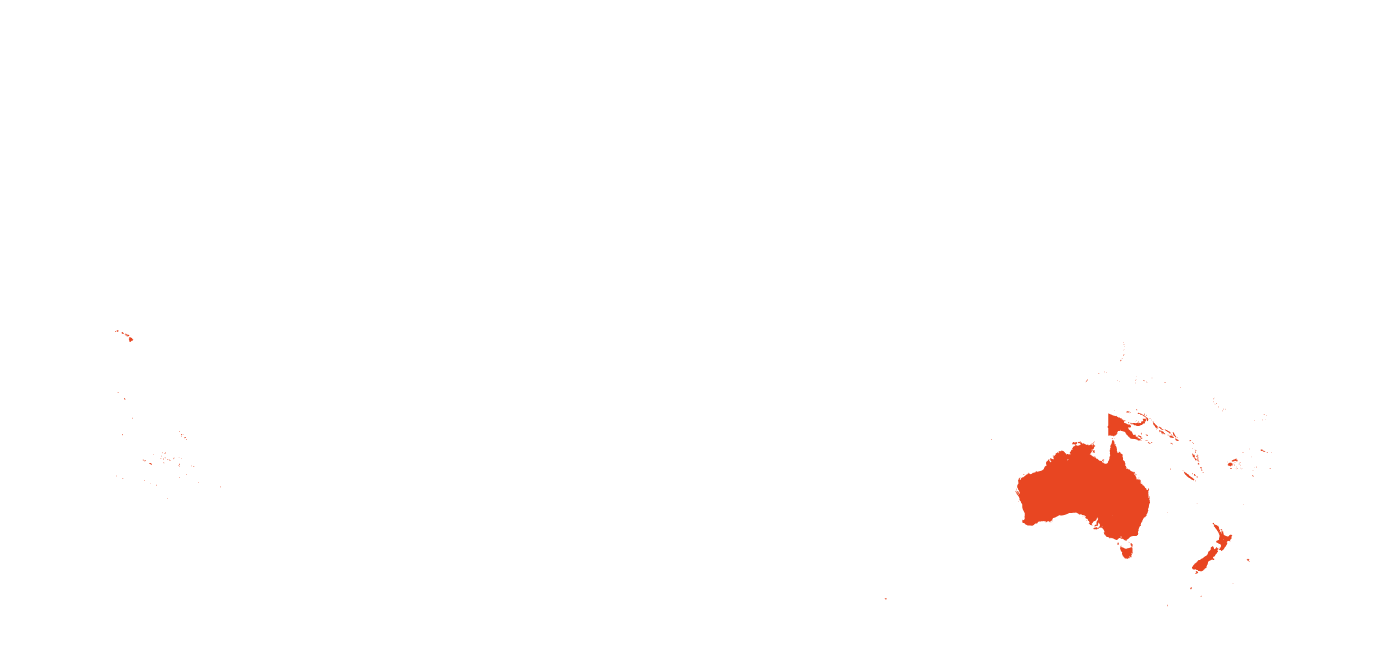

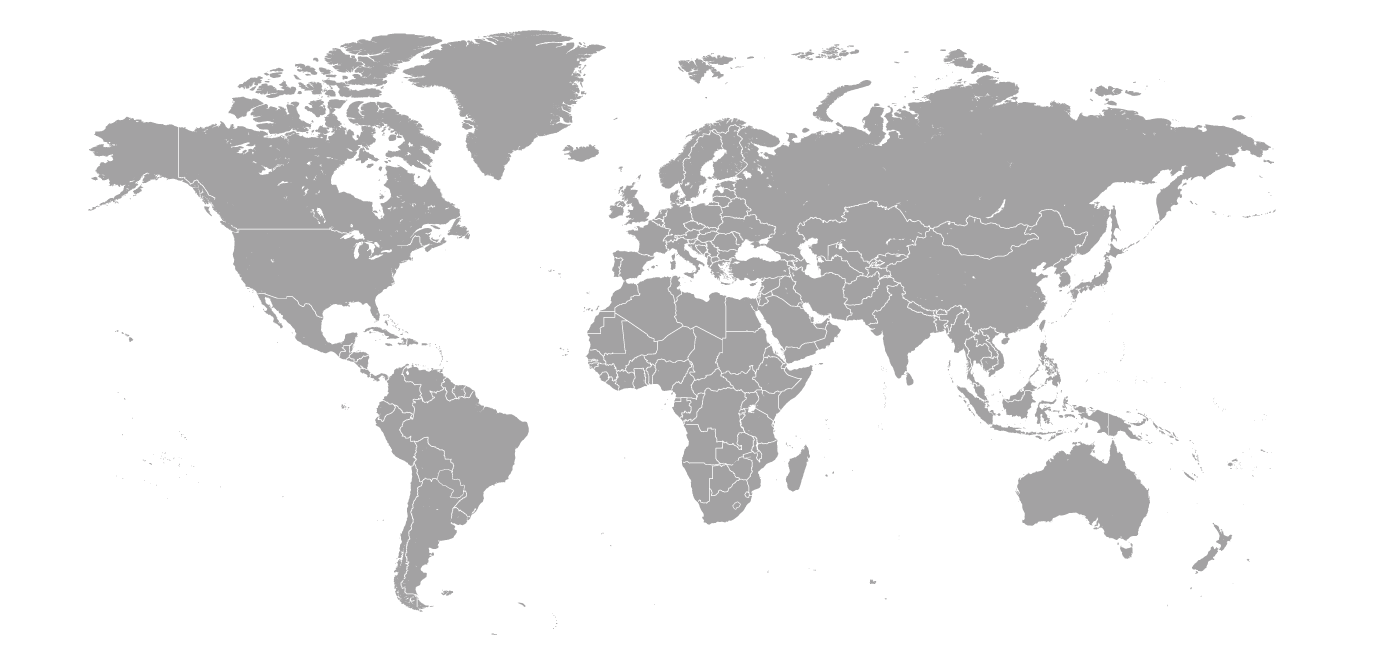

With a big range of filtrating, sedimenting and combination centrifuges SIEBTECHNIK TEMA has been able to provide ideal centrifuges to worldwide plants for the continuous solid — liquid separation of a broad range of polymers such as:

Acrylonitrile Butadiene Styrene (ABS), Acrylonitrile Styrene Acrylate (ASA), Expanded Polystyrene (EPS), High Density Polyethylene (HDPE), Methacrylate Butadiene Styrene (MBS), Polycaprolactam (PA6), Polycarbonate (PC), Polyhydroxybutyrate (PHB), Polymethyl Methacrylate (PMMA), Polyoxymethylene (POM), Polystyrene (PS), Polyvinyl Alcohol (PVAL, PVOH), Polyvinyl Butyral (PVB), Polyvinyl Chloride (PVC), Styrene Butadiene Copolymer (SBC), Ultra High Molecular Weight Polyethylene (UHMWPE), and many more.

The requirements for a successful solid — liquid separation are not just met by selecting the right type of centrifuge. For this purpose, SIEBTECHNIK TEMA is also specialized to deliver all the centrifuges with customized design features upon request, in order to fulfill the specific needs of the solid — liquid separation process. Optional features include the following:

- Gas tight design with inertisation

- Special surface treatment

- Custom designs of rotating parts

- Special materials and linings

- Sophisticated wear protection

- Housing insulation and / or heating

- Custom control solutions

The following centrifuge models in the delivery scope of SIEBTECHNIK TEMA are already successfully established in the continuous solid — liquid separation of the above-mentioned polymers:

Filtrating centrifuges:

- CONTURBEX screen worm centrifuge

- SHS pusher centrifuge

- TURBOCASCADE sliding centrifuge

Sedimenting centrifuges:

- SHORTBOWL decanter

- DZ & TS decanter

Combination centrifuges:

- TWINCONE decanter

- TURBOSCREEN decanter

As the market demands the development of polymers with enhanced characteristics, SIEBTECHNIK TEMA is able to provide laboratory evaluations and trials in pilot scale, often at the customer facilities in order to help the customer to find the optimal centrifuge equipment for the solid — liquid separation, early in product development.

CONTINUOUS FLUID BED DRYERS BY TEMA PROCESS

A fluidized bed is a physical phenomenon occurring when a quantity of a solid particulate substance is placed under appropriate conditions to cause a solid/ fluid mixture to behave as a fluid. A continuous fluid bed dryer/cooler is a machine in which a continuous flow of damp solid particles is conveyed over a perforated plate, through which air is blown to bring about fluidization.

The product is dried in the first section of the machine and cooled down in the second part. Drying occurs because of the direct contact between the “wet” material and the hot air blown through the material. The drying and cooling sections of the machine form a single conveyor in which the hot and cool air flows are segregated. Conveying of the product is achieved by means of a low-frequency, high amplitude shaker mechanism. The air which is used in the fluid bed performs two functions. First, the air flows through the layer of solids at a velocity sufficient to support the weight of the particles, which creates a fluidized state enabling the particles to flow. Second, the air in the fluid bed serves to cool, heat or dry the particles as it comes into direct contact with the solids material within the fluid bed chamber.

The rapid heat and mass transfer rates between the product and the drying medium and rapid mixing of solids which leads to nearly isothermal conditions throughout the fluidized layer, makes the fluid bed dryer an ideal system to dry polymers. The product is never heated or dried more than necessary and is always processed for the right length of time and at the right temperature. This results in predictable and consistent product quality. The “Shaking” motion plug flow of the TEMA PROCESS fluid bed dryer, allows a first-in, firstout drying of products and well mixed fluidization, which covers the entire spectrum and enables a control of the residence time.

Fluid bed dryers are specially preferred in the chemical industry in combination with after cooling and heat recovery, resulting in better end product quality and very low energy consumptions.

The temperature of the product must be carefully controlled. Often the particles tend to stick together, so the product needs continuous and gentle agitation. The drying system has to meet the design rate on throughput and all product quality specifications: purity, dryness, temperature and uniformity. The design of the drying processing equipment must include an explosion protection strategy. An ignition source is all that is required to initiate an explosion. TEMA PROCESS can implement a full line of explosion protection solutions including ATEX certified explosion vents, flameless explosion venting, explosion suppression systems, explosion isolation systems and explosion detectors but also fire suppression and fire extinguishers.

ADVANTAGES OF CONTINUOUS FLUID BED DRYERS BY TEMA PROCESS

Advantages of the fluid bed dryers by TEMA PROCESS include: Low energy consumption compared to other type of dryers, accurate control of the residence time, product is dried uniformly, gentle on sensitive materials (no friction), low operating costs, cooling section integrated in dryer, handling of sticky products, small footprint, process flexibility, reliable system, less downtime.

SIEBTECHNIK TEMA’s dewatering and drying solution for INEOS Styrolution’s new ASA plant in Bayport, Texas: A line mainly consists of a SHS pusher

centrifuge, a solid bunker and a two-stage dynamic fluid bed dryer. The process is designed for minimal energy consumption and exhaust air emissions. Furthermore, it includes a comprehensive explosion protection system.

Download the whole article here.

Find out more about INEOS and the new ASA plant here.